language

- Flexible high-performance bagging machines & palletizing systems

- Robot Case Packer System

- Top Loading Case Packer

- Fully automatic bagging, case packing and palletizing line

- VFS1100 Automatic Baling Machine for PE master bag

- Double hopper secondary packaging machine for PP woven master bag

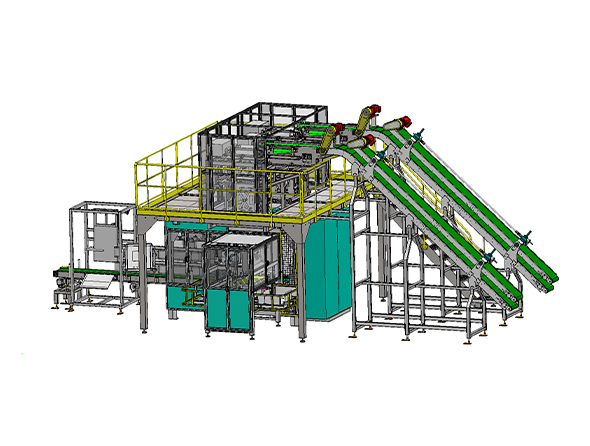

- Single hopper secondary packaging machine for PP woven master bag

- Single hopper secondary packaging machine for PP woven master bag

- ZENGRAN, Innovating of automatic bag-in-bag secondary packaging

·Double layer climbing conveyor

·Accelerating&Counting conveyor

·Bag flap device and shaping hopper

·Supporting platform

·Single hopper secondary packing machine

·Sewing machine& Sewing conveyor

·Double layer climbing conveyor

·Accelerating&Counting conveyor

·Bag flap device and shaping hopper

·Supporting platform

·Single hopper secondary packing machine

·Sewing machine& Sewing conveyor

·Check weigher

·Metal detector

·Robotic palletizing system

·To pack pouches of grains and powders into pre-formed bags,accurate primary bag counting, beautiful master bag shape.

·PP master bag replace carton box, save cost.

·To overcomes manual and disorderly packaging.

·1 double-hopper secondary packaging machine can be interlocked with 4 intermittent vertical packaging machines or 2 continuous vertical packaging machines, which can meet the requirements of 7x24 continuous production and improve production efficiency.

·It can be integrated with robot palletizing system to realize unmanned, automatic and intelligent production process.

|

Machine model |

ZYEDSP2AA |

|

Application of primary bag |

0.25-10kg (customized hopper according to product range) |

|

Max.infeed speed of primary bag |

120-150bags/min |

|

Packaging speed of master bag |

4-8 bags(PP woven bag) |

|

Master bag size range |

L(585-950)*W(350-450)*Gusset(70-150) |

|

Master bag material |

Open Mouth PP woven bag |

|

Power supply |

AC380V±5%,50HZ |

|

Max Power consumption |

12KW |

|

Air pressure |

≥6kgf/c㎡ |

|

Air consumption |

≤1m³/min |

|

Noise |

≤80 dB |

|

Machine material |

Painted steel frame+Contact part SS304 |

|

Machine weight |

7000kg |

+86 0551 68758887

+86 0551 68758887