language

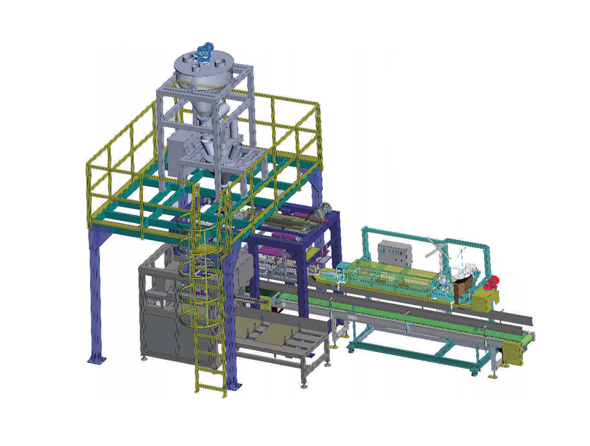

GFCK-M Equipped with vertical auger filler and dust-free product feeding and filling system, it is widely applied for the automatic packaging of powdery materials with strong viscosity, large dust fine powder, such as tapoica starch, whey protein powder, non-dairy creamer powder and agrochemical products, etc.

·Easy operation

·Sturdy construction

·Compact design

·High reliability

·Full machine stainless steel

·Dust collector

·Feeding elevator

·Bag labelling

·CIJ printer

·Robotic palletizing system

GFCK-M Equipped with vertical auger filler and dust-free product feeding and filling system, it is widely applied for the automatic packaging of powdery materials with strong viscosity, large dust fine powder, such as tapoica starch, whey protein powder, non-dairy creamer powder and agrochemical products, etc.

|

Section |

Items |

Specification |

|

Mechanical data |

Machine dimension(L*W*H) |

2780*3000*2370(main body) |

|

Machine weight |

4500kg |

|

|

Machine material |

Contact parts SS304+Carbon steel structure |

|

|

Bag size |

580*1000(can be customized) |

|

|

Bag type |

Flat open mouth bag, M-gusset bag |

|

|

Bag material |

PE, PP Woven, Kraft paper bag,etc |

|

|

Ambient temp. |

-10℃~35℃ |

|

|

IP grade |

IP56 |

|

|

Electrical data |

Power supply |

AC380V±10% |

|

Frequency |

50/60Hz |

|

|

Power consuption |

15kW |

|

|

Compressed air |

0.5~0.7Mpa |

|

|

Air consumption |

≤1000L/min |

|

|

Performance date |

Packing speed |

180~240BPH(25kg/ bag flour, vertical auger scale)

|

|

Weighing accuracy |

0.5% |

+86 0551 68758887

+86 0551 68758887